A valve is an object used to control the air and fluid from any pipe. It is used for directing, controlling, or regulating the fluid’s flow from the ducts. These devices close or open to partially block fluid passage and direct it to flow in specific areas. The valves open to allow fluid passage or stop fluid from flowing when they close.

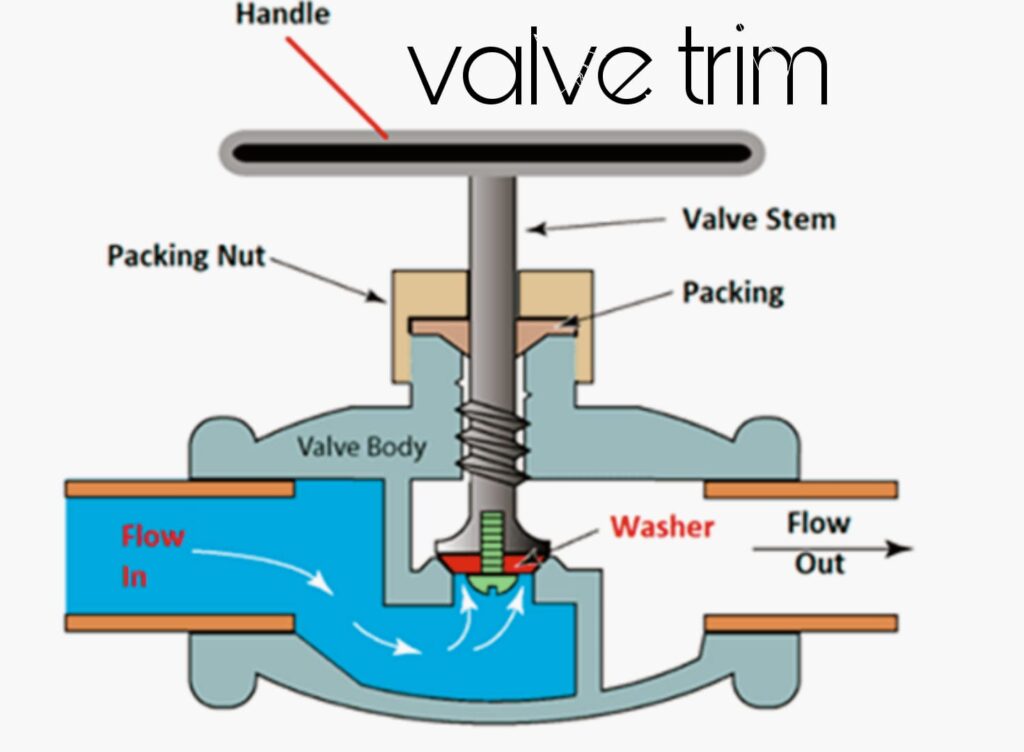

Valve trim is also a part of the valve on its inner side. These parts can be removed or replaced easily. The internal parts of the valve work together when any fluid, like liquid or gas, passes through the pipelines. The essential parts of all types of valves are almost the same. These parts of the valve are:

- Body of the valve

- Valve trim

- Valve’s bonnet

- Valve’s packaging

- And the actuator of the valve

Each part of the valve has its specific importance. To make the valve more efficient, the parts of the valves play an essential role. These parts have their unique properties and work. Detailed information about the valve parts is provided to you in this article.

Valve Trim:

The valve’s internal parts can be replaced or removed. When the fluid flow through the pipes are ducks, they combine and make their performances collectively along with their medium of flowing fluid. Valve trim is the collective term for all the parts of the valve’s body that come into contact to maintain fluid flow. Spacers, discs, disc nuts, Internet springs, guides, seats, and bushings are all internal parts of the valve’s body. And the combination of all these parts for the maintenance of fluid media is known as Valve Trim.

Sometimes the bonnet, body of the valve, and valve packing are referred to as the Valve trim because these parts also become active and combine when liquid flows through the ducks or pipes. But that statement is incorrect. It would be wrong to name these parts as valve trim. The actual valve trim term is for the parts of the valve that are present inside the body of the valve.

Performance Of The Valve Trim:

Every part of the wall valve has some significance and plays an essential role in the performance of the valve as a complete device. The function of the whole valve is dependent on the working of each part of it. The valve’s working is affected if any of the valve parts does not work correctly. So the normal working condition of all the parts is necessary for the valve to work correctly in the valve trim, the seat, and the disk interface. The specific orientation of the disk concerning the seat of trim is a necessarily considerable point. The relation between the seat and the disk’s position directly affects the valve trim’s performance.

The seat and the disk interface affect the valve trim’s operational performance. You can not neglect the role of all the constituent elements; they critically play in fluid flow, and controlling fluid flow is valve trim. The motions of the fluid are made possible with the help of valve trim. Controlling the liquid flow is possible by valve trim.

Valve Trim Designs:

Although all the valve trim parts are the same, the valve trims have different designs. These designs of the valve trim are based on the motion of the disc of the valve trim. This disk can move linearly as well as it can also move rotationally. The designs of valve trim are based on the linear motion of the disk or depend upon its rotational motion. Due to the linearity or rationality of the disc’s motion, valve trim has two types of designs. These designs of valve trim are:

- Linear motion trim design.

- Rotational motion trim design.

Linear motion trim design:

The disc lifts linearly in a linear motion trim design. In this design, the discs show perpendicular lifting to the seat. It lifts towards the seat to stop the appearance of an annular orifice, or it can allow the appearance of the orifice by moving the opposite side of the disc. Still, in each case, it will move perpendicularly. The orifice appearance by the lifting disc away from the seat allows the fluid to flow from the medium. This flow stops when the disc moves towards the seat and the orifice are disappeared.

Rotational motion trim design:

The disc slides close to the seat in this valve trim design. Such disc movement affects the flow opening and becomes the reason for flow opening changes. Both of these designs of valve trim have their specifications and importance at the places of their usage.

Construction Of Parts Of Valve Trim:

The material used for constructing valve elements is not the same for all parts. Varied types of materials are used for the formation of the valve trim. Each part of the valve trim has properties that are different from the others, due to which every part is constructed with different materials. The valve trim parts experience numerous forces and suffer from different states or situations.

If all the parts are constructed with the same material, then all of them will hold the same properties; as a result, they will not be able to handle all situations. These parts will not work as required while experiencing different forces. So for handling many conditions, or forces, all the valve trim parts are constructed with different materials and have unique properties that differ from the other parts. The forces faced by the seat and disc differ from those experienced by the other party of the valve, like packing glands.

Selection Of Materials For Valve Trim:

It isn’t easy to select which material should be used to construct trim parts. Different types of materials hold different properties. It is not impossible to find such materials that contain all your required properties. So, it is not easy to make decisions about constructing materials. There are many factors to consider before finalizing your material choice. The factors that you should consider while selecting material are listed below:

- Pressure

- Temperature

- Properties of the flow medium.

- Rate of the fluid.

- The viscosity of the fluid.

- The velocity of the fluid.

- Material’s chemical composition.

Two parts of that trim can be manufactured with the same material, like the bonnet and the valve’s body, but most are manufactured with different materials.

Components Of The Valve Trim:

As we know, valve trim is an internal part of the valve, and all of these parts contain properties. Disc, seat, back seat, stem, bonnet bolt, gland eyebolt, yoke, yoke bushings, gland flange, and stem packing are the leading valve trim parts. Each part has specific characteristics and its working function. A few most important components of the valve trim and their characteristics are discussed here.

Disc:

The part of the valve trim that allows the fluid to pass or prohibits the fluid flow by its position is called the disc. It can be manufactured. The shape of the disc is referred to as the name of the valve. For example, the shape of the disc for the ball, gate, or plug valves is just like the valve’s name. This component of the valve is also known as the pressure-maintaining part. The disc of the stationery valve seat doesn’t show any movement.

Seat:

The place of the valve trim for setting the disc is called the seat. The number of seats can vary for different valves. For example, the swing-check valve and the globe valves have single seats, while the number of seats on the ball and gate valves is two. These two seats are referred to as upstream and downstream, respectively.

The fluid leakage from the valve occurs if the connection between the disc and the seat is not properly maintained. So leakage is stopped by appropriately sealing the connection between the seat and the disc. The ring-shaped seats of valves also are removable. But in some cases, these seats are fixed for some valves. The connection between the disc and seat is made by screwing or welding.

Stem:

The part of the valve trim used for connecting the disk and actuator is called the stem. The stem’s movement depends upon the position of the disc. The stem’s movement causes the motion of the disc, which results in the allowing or stopping of fluid by closing or opening the valve. The disc moves linearly to open or close the valve of the glob or gate valve.

While the motion of the disc for the butterfly valve, plug valve, or ball valve, welcome to know that the disc shows rotational motion for the valve’s closing or valve opening. Almost all types of valves contain stem parts except two. The check valve and stop check valve are the only valves that do not contain a stem.

Apart from this, if you are interested to know more about The Importance Of A Sign Have Endless Possibilities For Your Business then visit our BUSINESS category.

FAQS

- What is valve trim?

The internal parts of the valve that directly connect with the flowing fluid through the duct or pipes are called valve trim.

- What types of discs can be shown?

The disk can move linearly or rotationally for the closing opening of the valve.

- Give a few examples of the valve.

Glob valve, Butterfly valve, Plug valve, Check valve, Ball valve, etc.